Why Steel Band Saw Blade Strips Are Essential for Optimal Performance in Heavy-Duty Cutting Operations

Round steel bars are vital components used in various manufacturing processes. These bars are known for their strength and versatility. They come in different sizes and grades, which makes them suitable for various applications. For instance, round steel bars are widely used in construction, automotive, and machinery industries. Their unique properties, such as resistance to corrosion and durability, contribute to their popularity.

When selecting a round steel bar, it’s crucial to consider its diameter and length. The specifications often depend on the intended use. For example, larger diameters are ideal for structural applications, while smaller sizes may be used for fabrication purposes.

Benefits of Using Round Steel Bars in Different Applications

Round steel bars offer numerous benefits that make them ideal for various industries. One major advantage is their strength-to-weight ratio. They provide high strength without adding excessive weight, making them perfect for applications that require both.

Additionally, round steel bars are easy to machine and fabricate. This characteristic allows manufacturers to create specific components efficiently. Moreover, they can be welded, which adds to their versatility in construction and manufacturing. The ability to customize round steel bars for specific needs ensures they remain a go-to material in many sectors.

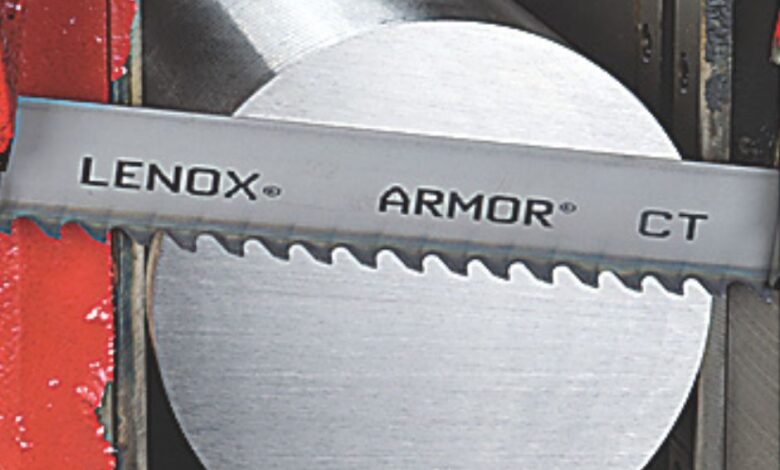

Exploring Steel Band Saw Blade Strips: Essential Tools for Cutting

Steel band saw blade strips play a crucial role in heavy-duty cutting operations. These blades are designed to deliver precision and efficiency in cutting various materials, including metals and plastics. The strength and flexibility of steel band saw blade strips allow them to tackle tough jobs with ease.

The manufacturing of steel band saw blade strips involves specific processes that enhance their performance. For example, high-quality steel is used to ensure durability and longevity. This makes the blades capable of withstanding the rigors of heavy-duty applications.

Advantages of Steel Band Saw Blade Strips in Cutting Operations

One significant advantage of steel band saw blade strips is their ability to provide clean cuts. When using a band saw, the blade moves continuously, allowing for smooth and accurate cutting. This feature minimizes the need for additional finishing processes, saving time and resources.

Moreover, steel band saw blade strips are cost-effective. They have a longer lifespan compared to other cutting tools, which reduces the frequency of replacements. Additionally, their efficiency in cutting can lead to less waste of materials, further enhancing their cost-effectiveness.

The Relationship Between Round Steel Bars and Steel Band Saw Blade Strips

Understanding how round steel bars and steel band saw blade strips interact can enhance overall performance in manufacturing. When working with round steel bars, using high-quality band saw blade strips is essential for optimal results. The precision of the cut directly impacts the quality of the final product. Therefore, combining the right materials with the appropriate cutting tools can significantly improve efficiency.

Ensuring Compatibility for Optimal Performance

When selecting steel band saw blade strips for cutting round steel bars, it’s vital to consider the specifications of both. The blade’s width, thickness, and tooth design must match the properties of the round steel bar. This ensures that the cutting process is smooth and effective, preventing damage to both the blade and the material being cut.

Moreover, regular maintenance of both the round steel bars and the steel band saw blade strips is essential. Proper upkeep extends the lifespan of both materials and tools, ensuring ongoing efficiency in cutting operations.

Frequently Asked Questions

What Are the Common Uses of Round Steel Bars?

Round steel bars are commonly used in construction, automotive, and machinery manufacturing. Their strength and versatility make them ideal for various applications, including support beams and components.

How Do Steel Band Saw Blade Strips Work?

Steel band saw blade strips work by continuously moving in a loop, allowing for smooth and precise cuts. They are designed to handle tough materials, ensuring efficiency in cutting operations.

What Factors Should I Consider When Choosing a Round Steel Bar?

When choosing a round steel bar, consider the diameter, length, and grade of the steel. The intended application will determine the specific requirements for these specifications.

How Can I Maintain Steel Band Saw Blade Strips?

To maintain steel band saw blade strips, keep them clean and properly lubricated. Regular inspections for wear and damage are also essential to ensure optimal performance.

Why Are Round Steel Bars Preferred in Construction?

Round steel bars are preferred in construction due to their high strength, durability, and ease of fabrication. They can be customized for specific applications, making them versatile.

Conclusion

In conclusion, round steel bars and steel band saw blade strips are essential components in heavy-duty cutting operations. Their unique properties and advantages contribute significantly to the efficiency and quality of manufacturing processes. By understanding their characteristics and how they interact, manufacturers can optimize their use for various applications. Investing in high-quality materials and tools not only enhances performance but also leads to long-term cost savings. Whether you’re in construction or manufacturing, recognizing the value of these products will undoubtedly improve your operations.